Sustainability through Responsibility

PRODUCTS AND SERVICES

Our engineered composite repair technology provides complete structural repair and reinforcement solutions that are safe, flexible, practical, and cost-effective.

- Strongpipe ® Engineered Composite Repairs

- Strongpipe ® Structural Repair Clamps

- Strongpipe ® Internal Weld Sleeves

- Strongpipe ® Pipeline Emergency Repair Clamps

COMPOSITES FOR PIPE REPAIR SYSTEMS

01.

Strongpipe®

Vacuum Epoxy Reinforcement

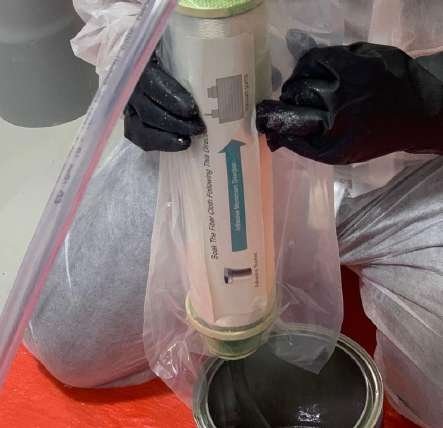

Strongpipe Vacuum Epoxy Reinforcement and Glass Shield Wrapping Systems use a more optimal reinforced clamp structure for onsite vacuum installation.

Instead of using the traditional perfusion process, which injects the adhesive with positive pressure, the process uses the negative pressure created by vacuuming to perfuse the epoxy. This enhancement provides the system with much more consistent performance. The vacuum pump will be used in the field to suck the evenly mixed high strength epoxy. Under the effect of vacuum negative pressure, the epoxy will be able to enter any tiny gaps and leave no cavity behind. The thoroughly filled epoxy composite

material has good adhesion and compressive strength. Once cured, the pipelines and reinforcement will become a single one-piece structure, and the stress on the pipelines will be effectively shared, ensuring reliable reinforcement performance.

02.

Strongpipe® S Glass

All our repairs are designed in line with ISO 24817 ASME PCC 2 standards and can be warranted for

20 year design life, thus extending the life of critical infrastructure.

S-glass Fibreglass is a high performance alternative to standard Fibreglass E-glass. It is stronger and stiffer with a comparable density. S-glass Fibreglass is more expensive than E-glass but is still cheaper than Carbon Fibre. It is a good alternative for laminates requiring high strength.

03.

Strongpipe® V-WrapTM Carbon Fiber

System For Pipe Strengthening

StrongPIPE V-WrapTM Carbon Fiber is a structural strengthening system for the restoration and renewal of concrete, metallic and polymer-based pipelines. The system has been tested and meets or exceeds durability requirements (ICC-ES) necessary to provide the desired service life for pipeline structures.

04.

Strongpipe® Outershield GF

Outershield MC710-H is widely applied in industry and has gained popularity because it combines ease of use and high productivity with good mechanical properties.

Being one of the best consumables in this group, it reflects typical advantages of metal cored wires. Metal cored wire, such as Outershield MC710-H, is a very good solution for thin sheet material, and is also one of the best solutions for semiautomatic welding of multipass welds and thicker plates. Metal cored wire, however, is typically not considered a low-fume generating welding process.The FER for the MCAW (M21) process is typically lower than the FER of the GMAW (CO2) process and higher than the FER of the GMAW (Pulse) process.